High-Performance PCP Solutions

Engineered for durability and B2B profitability.

High-Pressure Hand Pumps

- Feature 3-Stage & 4-Stage designs, Grade 304 Stainless Steel.

- Advantage Superior heat dissipation under 4500 PSI loads.

- Benefit Reduce Returns: Ultra-durable build minimizes warranty claims.

PCP Air Compressors

- Feature Auto-Shutoff Technology & Water/Oil Separators.

- Advantage Fills faster while preventing moisture damage to air guns.

- Benefit High Satisfaction: Plug-and-play solution drives repeat sales.

Portable 12V PCP Compressor

- Feature 12V DC powered, lightweight design (under 8kg), built-in LCD display & auto-shutoff at preset PSI.

- Advantage Fills PCP rifles anywhere—car, field, or off-grid—without AC power dependency.

- Benefit Expand Your Market: Tap into outdoor enthusiasts & mobile shooters who demand portability.

Air cylinder valve

- Feature Precision-machined brass/stainless steel construction, adjustable output pressure (800-4500 PSI), integrated burst disc safety.

- Advantage Drop-in replacement for major PCP brands with leak-free sealing and smooth pressure regulation.

- Benefit Fast Turnover: High-demand replacement part with excellent profit margins and repeat buyers.

Air Tank Cylinder

- Feature Carbon fiber & aluminum alloy construction, 0.35L-6.8L capacity options, rated 4500 PSI (300 bar) with DOT/CE certification.

- Advantage Ultra-lightweight design (50% lighter than steel) with 15-year service life and visual damage inspection.

- Benefit Cross-Sell Opportunity: Premium product commands strong margins while meeting international safety standards.

High Pressure Gauge

- Feature Glycerin-filled dial, luminous face, 1/8" NPT & M10 threads, dual-scale display (PSI/BAR), 0-6000 PSI range.

- Advantage Vibration-dampened accuracy (±1.5%) with clear readings in low-light conditions.

- Benefit Premium Upsell: Consumable Revenue: High-frequency replacement item generates steady repeat orders.

Scuba Diving Breathing Air Compressor

- Feature 4-stage filtration system (oil/water/particulate/activated carbon), 100L/min flow rate, 4500 PSI max pressure, CE/EN 12021 breathing air certified.

- Advantage Removes 99.9% oil vapor, odor, and contaminants—safe for direct human respiration.

- Benefit Replacement Market: Tap into the lucrative scuba diving industry with certified breathing-grade equipment.

Aluminum air tank air cylinder

- Feature 6061-T6 aerospace-grade aluminum, hard-anodized finish, 0.35L-1.1L capacities, rated 3000-4500 PSI with DOT/TC certification.

- Advantage 40% lighter than steel at half the cost of carbon fiber—ideal price-performance balance.

- Benefit Safety Compliance: Affordable entry point drives high unit sales and first-time buyer conversions.

PCP Maintenance Kits

- Feature O-ring sets, lubricants, seal kits for all major brands.

- Advantage Complete DIY repair solution, extends equipment life.

- Benefit Recurring Revenue: Consumables drive steady reorders.

Ready to Unlock Better Margins & Reliable Supply?

Join 500+ distributors worldwide who've transformed their PCP business with our factory-direct partnership. No middlemen, no quality surprises, no communication headaches – just consistent products that protect your reputation and grow your profits.

- Factory-Direct Wholesale Pricing – Save 20-40% compared to resellers with transparent pricing, no hidden fees

- 24-Hour Quote Guarantee – Fast response from dedicated account managers who speak your language

- 100% Pre-Shipment Inspection – Every unit tested before dispatch; detailed QC reports included

- Low MOQ & Flexible Orders – Start small with just 10 units; scale up as your business grows

- OEM/ODM & Private Label Ready – Custom branding, packaging, and specifications to match your market needs

Get Your Exclusive Wholesale Pricing

Fill out the form below and receive your personalized quote within 24 hours.

Where Our PCP Equipment Powers Performance

From recreational airguns to life-critical diving systems—our high-pressure solutions serve diverse industries worldwide.

PCP Airguns & Hunting

High-pressure hand pumps, compressors, and tanks designed for PCP air rifles. Trusted by hunters and sport shooters demanding consistent, reliable fills in the field.

Scuba Diving

Breathing-air compressors with 4-stage filtration meeting EN 12021 standards. Delivers clean, dry air for recreational and professional dive operations.

Paintball Sports

Lightweight carbon fiber and aluminum HPA tanks, quick-fill adapters, and portable compressors built for the fast-paced demands of competitive paintball.

Fire Fighting & Safety

High-pressure compressors and SCBA cylinder filling systems for fire departments and industrial safety teams. Reliable performance when lives depend on it.

Aquatic plant cultivation

High-pressure CO2 systems and precision regulators for aquarium and hydroponic applications. Delivers stable, controlled CO2 injection to promote lush plant growth in aquascaping and commercial aquatic farming.

Beverage industry production line

Food-grade compressors and carbonation systems for beverage manufacturing. Supplies clean, high-pressure CO2 for carbonation processes, nitrogen for packaging, and compressed air for automated production lines.

Don't see your industry? We customize solutions for unique applications.

Why Partner With TOPA?

We bridge the gap between low-cost sourcing and high-quality reliability for PCP equipment.

One-Stop Procurement

Feature: Full range of PCP pumps, compressors, tanks, and accessories.

Benefit: Eliminate multi-vendor chaos. Consolidate orders and save on logistics costs.

Expert Engineering Team

Feature: In-house experienced engineers for rapid design and quotation.

Benefit: Fast response times. Get professional solutions tailored to your needs.

Rapid OEM/ODM

Feature: Complete customization with your branding and specifications.

Benefit: Speed to market. Launch your branded PCP line faster than competitors.

Factory Direct Pricing

Feature: Direct access to our manufacturing facilities.

Benefit: Competitive pricing with guaranteed quality and delivery schedules.

Global Export Experience

Feature: Exported to 20+ countries including USA, UK, Germany, and Australia.

Benefit: Proven logistics expertise. Hassle-free international shipping and documentation.

Lifetime Support

Feature: Permanent stock of spare parts and dedicated technical support.

Benefit: Risk mitigation. Service your customers with confidence, ensuring long-term loyalty.

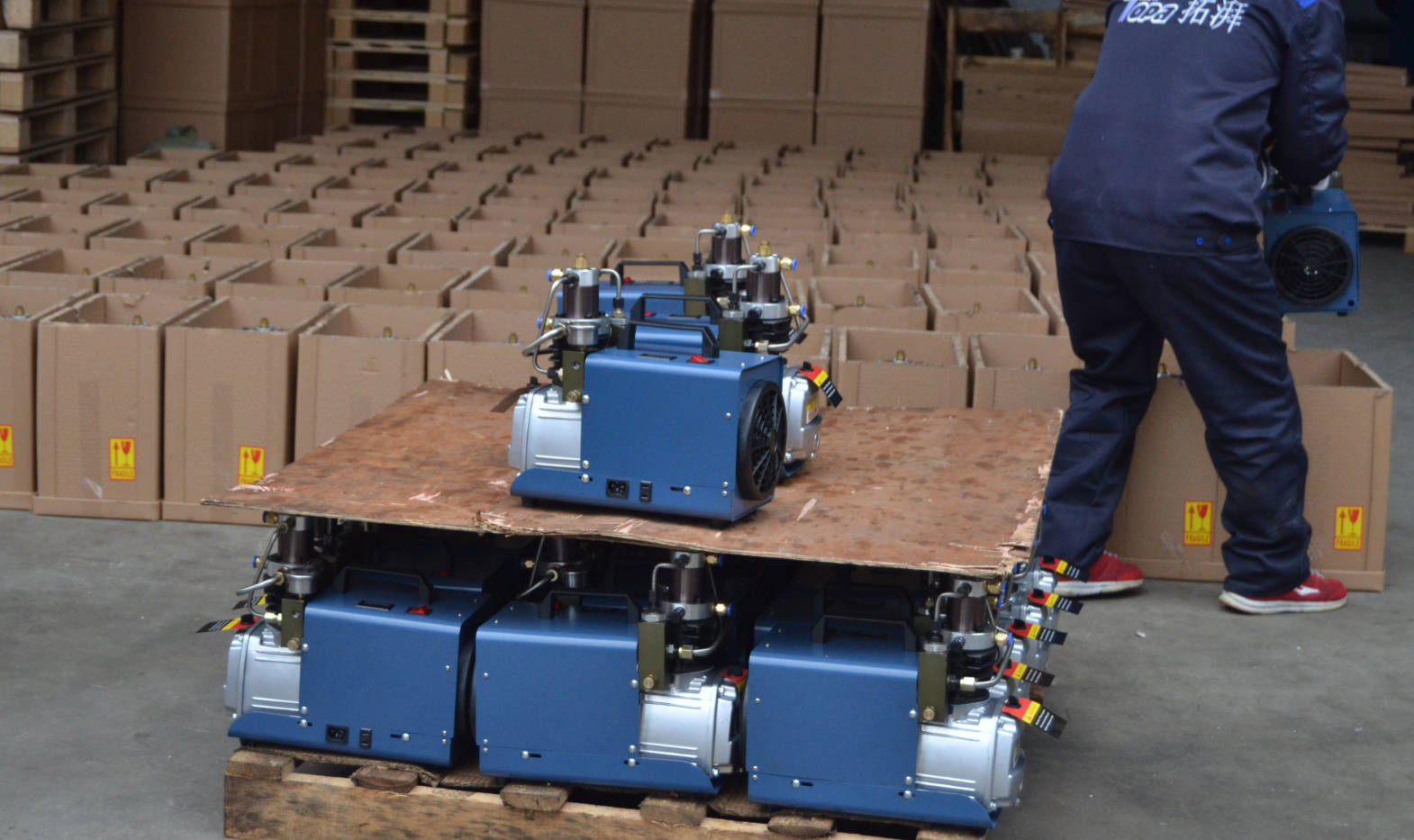

Production Process

Rigorous standards at every stage of the PCP manufacturing line.

Raw Material Verification

Every component starts with certified raw materials. We source high-grade aluminum alloys and quality steel from audited suppliers, then verify hardness, composition, and surface quality before production begins. This upstream control eliminates defects at the source—so you receive products that pass your customers' inspections the first time.

Precision CNC Machining

Our CNC machining centers achieve tight tolerances, ensuring perfect seal surfaces and thread fits. Automated tool monitoring and in-process measurement catch deviations instantly. The result: components that assemble smoothly, perform reliably, and dramatically reduce your warranty claims.

Functional Assembly

Trained technicians assemble each unit using calibrated tools and documented procedures. Critical connections—valves, gauges, and seals—are fitted with care to ensure leak-free operation. This disciplined approach means your customers get consistent, ready-to-use products out of the box.

Pressure & Performance Testing

Every unit undergoes a full-cycle pressure test above its rated working pressure. We verify flow rates, gauge accuracy, and auto-shutoff functions before sign-off. Units that fail are rejected—not reworked. This rigorous standard protects your brand reputation and keeps field failures to a minimum.

Final Inspection & Packing

Before shipping, QC inspectors check cosmetics, labeling, and accessory completeness against your specifications. Products are then packed in reinforced cartons with protective inserts to survive international freight. You receive inventory that's shelf-ready—no sorting, no surprises, no delays to market.

About Our Factory

Our facility focuses on the assembly and testing of high-pressure PCP equipment.

Built for Precision.

Designed for Scale.

Our modern facility combines advanced CNC machining, climate-controlled assembly areas, and comprehensive testing stations. Every square meter is optimized to deliver consistent quality at the volumes you need—whether you're ordering samples or full containers.

See How We Work

Get an inside look at our production facility, quality control process, and the team behind your orders. We believe transparency builds trust—and trust builds long-term partnerships.

Video is playing on mute. Click the speaker icon to unmute.

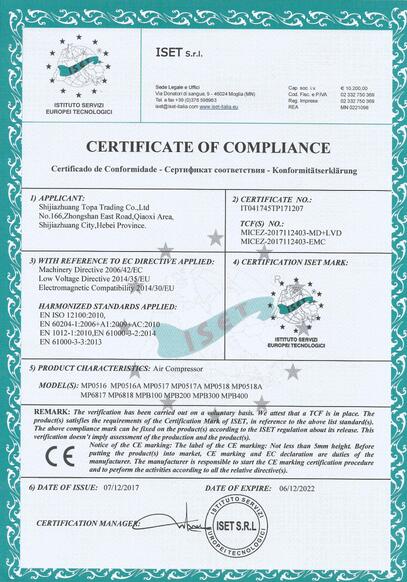

Verified Quality

Compliance with CE, ISO, and High-Pressure Safety Standards for seamless entry into EU and US markets.

CE

European Conformity

Meets EU safety, health, and environmental standards. Your products clear customs faster and sell confidently across all European markets.

ISO 9001

Quality Management

Our certified quality system ensures consistent production standards. Every batch meets the same specifications—reducing your QC burden and customer complaints.

100% Tested

Full Inspection

Every single unit is pressure-tested before shipment. No sampling, no shortcuts. You receive only products that passed our strict quality gates.

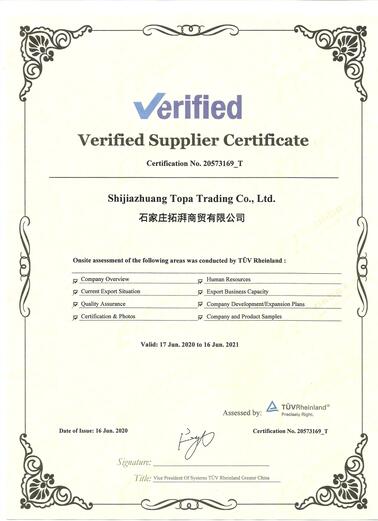

TUV

Third-Party Verified

Independent German certification confirms our safety claims. Gives your customers confidence and strengthens your brand credibility in competitive markets.

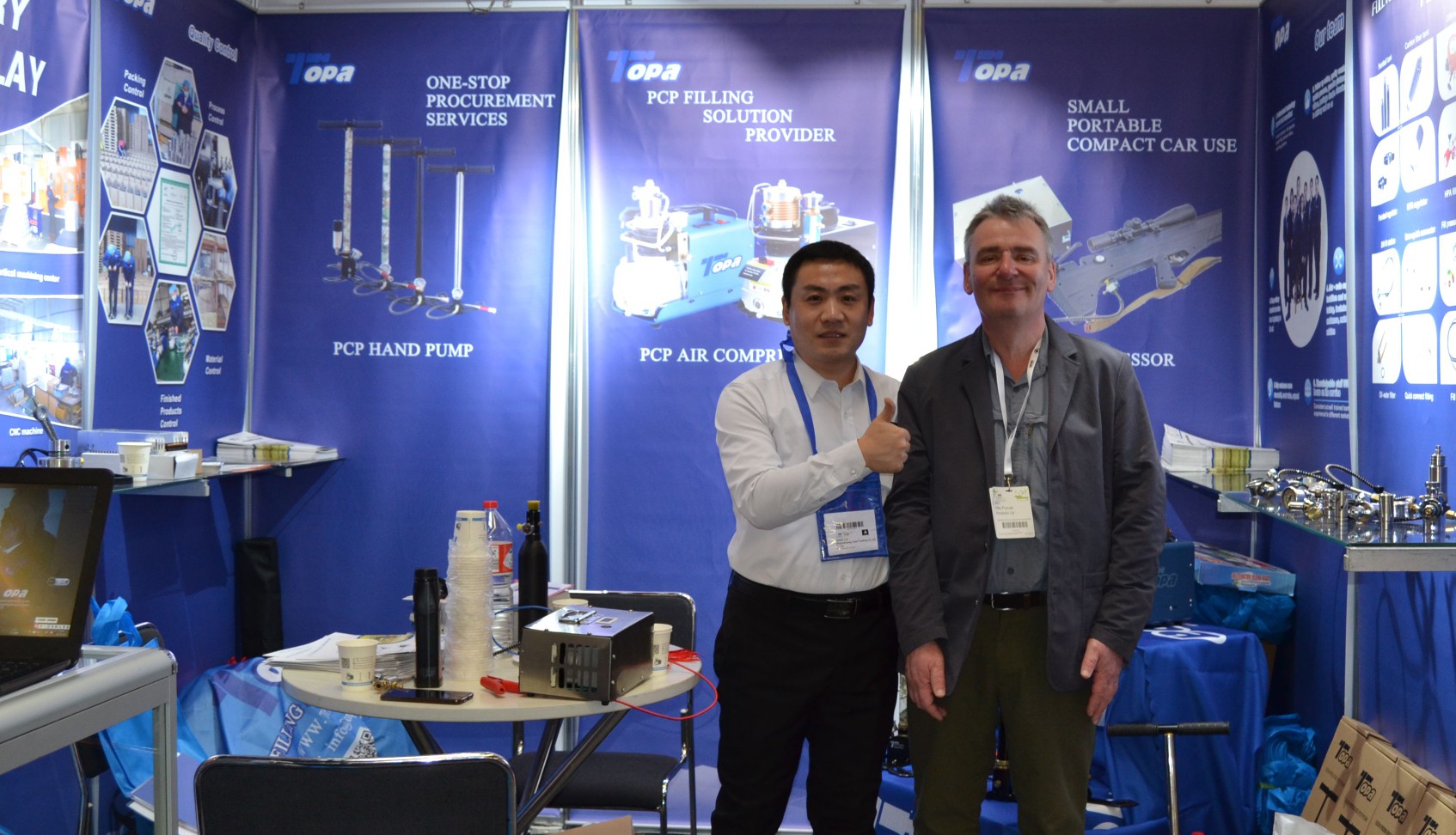

Our Global Presence

Building lasting partnerships face-to-face at major international trade shows. Meet our team, see our products in action, and discover why distributors worldwide choose TOPA.

Distributor Success Stories

Join hundreds of wholesalers who have scaled with TOPA.

"Reliability was our biggest issue with previous suppliers. TOPA's compressors have a return rate near zero, which has drastically reduced our aftermarket service costs. Our customers trust our brand more now."

"We needed a custom valve design for a new air rifle line. TOPA's engineering team turned around a prototype in two weeks. They aren't just a factory—they are a true strategic partner for growth."

"Communication and lead times are what set TOPA apart. They respond within hours, not days. Our last three container shipments arrived on schedule. That kind of reliability is rare in this industry."

Frequently Asked Questions

Everything you need to know about partnering with TOPA for PCP equipment wholesale.

Ready to Unlock Better Margins & Reliable Supply?

Join 500+ distributors worldwide who've transformed their PCP business with our factory-direct partnership. No middlemen, no quality surprises, no communication headaches — just consistent products that protect your reputation and grow your profits.

- Factory-Direct Wholesale Pricing — Save 20-40% compared to resellers with transparent pricing, no hidden fees

- 24-Hour Quote Guarantee — Fast response from dedicated account managers who speak your language

- 100% Pre-Shipment Inspection — Every unit tested before dispatch; detailed QC reports included

- Low MOQ & Flexible Orders — Start small with just 10 units; scale up as your business grows

- OEM/ODM & Private Label Ready — Custom branding, packaging, and specifications to match your market needs

Get Your Exclusive Wholesale Pricing

Fill out the form below and receive your personalized quote within 24 hours.